New Publication available

Ronja Heming,L. Grieser,K. Averkamp,Kerstin Wohlgemuth

https://doi.org/10.1016/j.seppur.2026.136892

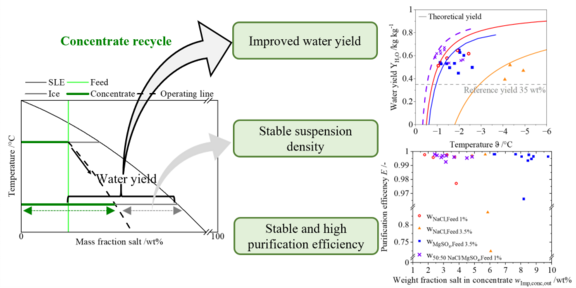

Suspension melt crystallization is a low-energy purification technology with growing potential in fields such as water and wastewater treatment. To increase melt (water) yield without compromising purity, we studied the impact of internal concentrate recycling on the performance of an integrated suspension melt crystallization pilot plant combining a scraped cooling crystallizer and a mechanical piston-type wash column. Systematic recycling experiments were conducted for three aqueous model systems NaCl–H₂O, MgSO₄–H₂O, and a mixed NaCl/MgSO₄–H₂O solution under controlled suspension densities and stepwise decreasing operating temperatures. A key observation is that the process concentrate concentration deviates from solid–liquid equilibrium (SLE), primarily due to heat-transfer limitations that limit crystal growth despite near-equilibrium operating temperatures. Additionally, the study identifies challenges related to ice entrainment in the recycle and demonstrates partial mitigation strategies to improve process stability. Overall, concentrate recycling shifts the process trajectory within the SLE diagram, enabling higher concentrate levels and maximizing water yield while maintaining high purification efficiency (>99%) and stable operation. The results further indicate that the developed operating strategies are transferable across systems with both known and unknown phase equilibria. Overall, the study highlights that controlled concentrate recycling can enhance production capacity while preserving purification efficiency.