New Publication available

Sophia Volpert, Lisa Nordhausen, Richard Alfsmann, Gerhard Schembecker

https://doi.org/10.1002/jssc.70339

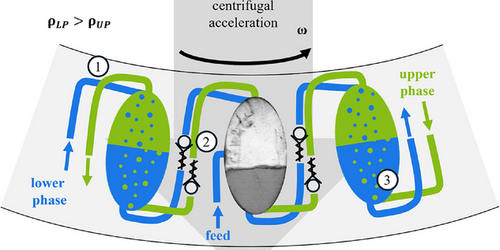

This study introduces an innovative method for continuous multistage liquid–liquid extraction. Addressing challenges like coalescence and settling times that limit efficiency makes centrifugal partition extraction a promising technique for continuous product separation. It combines the benefits of a mixer-settler cascade with centrifugal extractors in one compact apparatus. The working principle is based on centrifugal partition chromatography, where two immiscible liquid phases are contacted inside a rotor, one serving as the mobile phase and the other as the stationary phase. In centrifugal partition extraction, both phases are mobile. The rotating apparatus allows dispersion and reduces settling time compared with static settlers, with its 300 times higher acceleration. To overcome constructional challenges, a novel concept, termed counter-current centrifugal extraction, is introduced in this work. Thereby, the primary objective is to validate the hypothesis that the process is feasible with a modified rotor design consisting of 10 chambers connected by individual ducts. Combined with alternating pump directions, this enables a pseudo-continuous counter-current flow. A proof of concept is investigated using computational fluid dynamics. The methodologies employed yield valuable insights into hydrodynamic performance. Based on these simulations, an optimized geometry for the flow area is developed, where 100% of the total chamber height is utilized as a dispersion zone compared with the previous 45%. The improvements result in elliptical chambers inclined at 35° to the radial direction, with a height of 6 mm and a volume of 1.43 mL. Additionally, baffles are placed inside the chambers opposite to the two inlets, enhancing dispersion of the inflowing phases. Finally, during alternating operation mode, it is demonstrated that ducts with a volume of 0.17 mL lead to an alternating phase ratio between 0.48 and 0.57 inside the chambers, which was repeatable over five simulated switches. This confirms the feasibility of the concept proposed based on hydrodynamics.