New Publication available

Ronja Heming, Okan Yilmaz, Kerstin Wohlgemuth

https://doi.org/10.1016/j.seppur.2025.134411

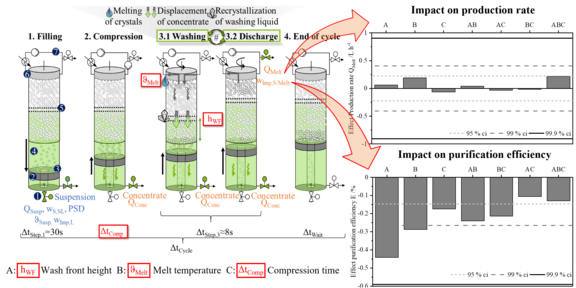

The development of efficient and environmentally friendly industrial purification technologies is a key trend in the chemical industry. This study focuses on suspension melt crystallization (freeze concentration), which has garnered significant attention due to its exceptional purification efficiency and low energy consumption, particularly when utilizing renewable energy sources. This technology presents a promising alternative for dewatering processes such as desalination and wastewater treatment. To fully leverage the advantages of suspension melt crystallization, effective solid–liquid separation and crystal purification are crucial, typically achieved through continuously operated wash columns integrated with crystallization units. However, the intricate operation of these columns necessitates a comprehensive understanding of how various process parameters impact their operational range and purification efficiency. In this research, a systematic experimental approach using a binary aqueous model system with sodium chloride was employed to evaluate the performance of a mechanical piston-type wash column equipped with a melt loop. Three critical process parameters were investigated: wash front height, melt loop temperature, and compression time of the piston. Our findings indicate that within stable operating conditions these parameters significantly influence the purification efficiency by maintaining a constant production rate. Notably, optimizing the wash front height and melt loop temperature led to an impressive purification efficiency of approximately 99.9% at lower values for both parameters. These results highlight the potential for enhanced operational performance in industrial applications and underscore that the melt temperature is also a critical parameter for process control.